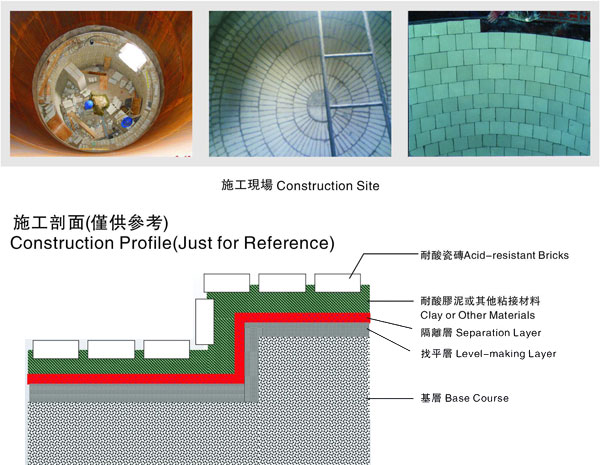

Construction & Maintenance

Points for attention during constructing KP I acid-resistant, heat-resistant clay.

• Before construction, the layer of carbon steel should be ejected with sand to remove the rust, the dust on the surface of concrete equipment should be cleaned off, and smoothed, and water content of the sink, pool made of concrete should be less than 6%. • The surface of acid-resistant bricks and granite used in liner-building should be clean and dry. • Containers for stirring clays should be clean and dry. • Unless the temperature on the construction site is between 15 and 35 centigrade, air moisture lower than 80%, the construction can go, if higher than 80%, ventilating and moisture-removing equipments should be strengthened. • Weighing potash silicate in the right materials-mixing proportion for KP-1 clay into stirring machine or containers, and then adding rightly-weighed KP-1 powder material, finally fully stirring evenly. Every time the amount of KP-1 clay should be used up within 30 minutes. • During construction, KP-1 clay is forbidden to replenish powder material and potash silicate, and should be refused to use if found to be hardened. • When building acid-resistant ceramic tiles and vitrolites, clays should be fully applied with hard pressing, and squeeze the clays out of crack, scrape off excessive clay with scraping knife, and binding layer and crack are usually 3-5 mm. • To prevent acid-resistant ceramic tiles from moving, it should be supported and fixed when building big ceramic tiles. • After-building equipments must be maintained in the surrounding with the temperature of being higher than 15 centigrade for over 14 days, and during maintenance period, it is forbidden to touch water and water vapor. • When constructing outdoors, water-proof and anti-sunbathing shelters should be put up.