Acid-resistant Clay

(A), KPI series of acid corrosion resistant properties of the materials and features

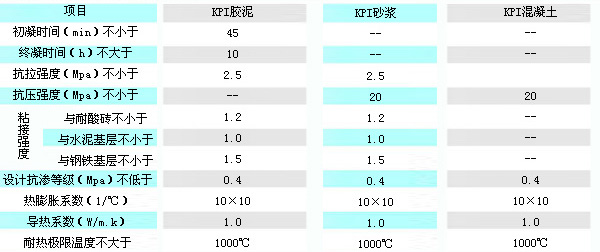

Series of acid-resistant clay KPI technical performance:

1, KPI series of potassium silicate clay as a bonding agent is inorganic molecular materials for the curing agent, aluminosilicate acid fillers for the composition of multiple copies of the stress has to be a strong new anti-corrosion materials.

2, KPI clay has a high mechanical strength and excellent adhesive properties, particularly in the granite block masonry materials, acid tiles, porcelain and cement the bond is greater than the mother.

3, KPI, Department of acid-resistant materials in a variety of concentrations of organic acids, inorganic acid stable, especially in acid, industrial water, neutral solution does not produce crystalline salt, and has a high impermeability.

4, heat resistance, the titanium rotary kiln lining, the use of temperatures up to 900 ℃ -1000 ℃.

5, KPI clay non-toxic curing agent, the operator of the construction workers no poison, identified by the medical and health sector, can be used for food, medicine and other equipment corrosion engineering.

6, KPI clay and organic acid-resistant material than the low price. It addition to corrosion resistance of organic clay, the same performance, but also has strong resistance to oxidation corrosion of the unique properties of the media.

7, room temperature curing, simple construction, easy to use, easy to transport, moisture-proof storage.

(B), KPI series of acid resistant materials, the scope and purpose

KPI clay can be used for a variety of concentrations of sulfuric acid, hydrochloric acid, nitric acid, phosphoric acid, chromic acid, hypochlorous acid, chlorosulfonic acid, formic acid, oxalic acid, acetic acid, various organic solvents, all kinds of acid salts, chlorine, hydrogen peroxide and other oxidizing medium, and the mixture of the above types of media.

KPI clay can be widely used in petroleum, chemical, metallurgy, electricity, pesticides, food, fermentation, hydrolysis, acid and other industrial sectors of the reactor, tank, tower pool, floor, trench, anticorrosion, etc. in the cell.

(C), KPI series of physical and mechanical properties of materials

(D), KPI acid corrosion resistance of heat-resistant series

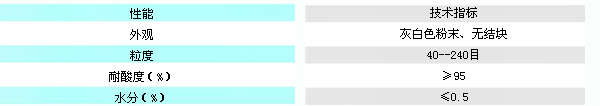

(E), KPI indicators of acid-resistant clay powder technology

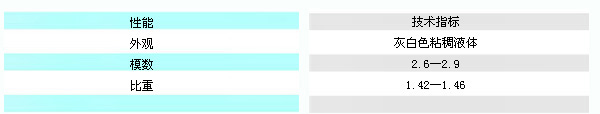

(F), silicate charge performance specifications

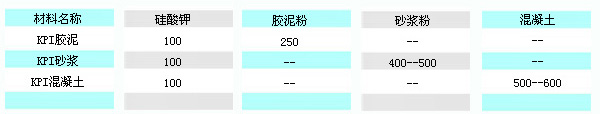

(G), KPI Series clay weight ratio of ingredients

(H), KPI acid resistant clay Construction Notes

1, before the construction of carbon steel equipment surfaces should be sand-blasting, concrete equipment should be dust from the surface uneven parts and repair of concrete to build the tank, the pool water should be less than 6%.

2, acid-resistant bricks used for lining plate, granite surface should be clean and dry.

3, mixing clay containers, utensils should be clean and dry.

4, the construction site, the temperature should be between 15 ℃ -35 ℃, ambient air humidity should be less than 80% of the construction, if more than 80% should be added ventilation dehumidification facilities.

5, according to KPI clay mixture ratio by adding potassium silicate weigh blender or mixing container, then add a good KPI, said powder, stir evenly. The amount of clay for each KPI stirring within 30 minutes should be used.

6, KPI clay during the construction of additional non-powder and potassium silicate, hardened clay should be discarded if found to do.

7, acid brick lining board, clay smear should be full and hard compacted clay out of the cracks between the blocks, and use a spatula to scrape off the excess clay, with layers and joints typically 3-5mm.

8, acid-resistant bricks lining large, in order to prevent the acid brick movement should be supported fixed.

9, the lining of the equipment to be higher than 15 ℃ in the health environment of more than 14 days, and health during exposure to water and water vapor is strictly prohibited.

10, the open-air water-resistant construction should prevent exposure to build sheds.

11, after health before use clay KPI KPI clay with special treatment solution 4 times, once every 4 hours treatment.

(Ix), KPI acid resistant mortar, scope and construction requirements

1, KPI acid resistant mortar can be used in chemical, light industry, metallurgy, metallurgical and other industrial plants in the beams and columns, bay windows, towers, floors, walls, grooves and other corrosive environments.

2, KPI mortar can be applied overall thickness of 10-20 mm, cell construction, cell spacing of 2-3 m slit, slit width can be 15-20 mm, fissures filled with compact clay.

3, KPI bulk granite mortar lining can also be combined with layers and joints generally 10-15 mm.

4, KPI KPI clay mortar construction requirements and construction of the same.

(X), KPI range of acid resistant concrete and construction requirements to adapt

1, KPI concrete can be used in chemical, light industry, metallurgy, acid, oil, pesticides, food, electroplating, electrolysis and other industrial sectors of the reactor, tank, tower, cell, trench, floor, fermentation pools as a whole, casting, or lining, can be used as the structure after adding anti-corrosion steel equipment.

2, the internal cast in carbon steel equipment, the construction of carbon steel equipment when the surface should be sand-blasting, the concrete cast inside the device when the device should be the surface of the oil, dust, clean up.

3, the casting must be strict with the module structure, size, accuracy, and has sufficient rigidity, height of 50 cm is appropriate.

4, the construction should be oiled before the template surface, and then the plastic membrane lining in the template surface, joints extend 5-10 cm.

5, mixing containers and tools must be clean and dry.

6, the construction site, the temperature must be above 15 ℃, the rainy season should be set up against the construction canopy.

7, according to KPI and potassium silicate concrete Mix thoroughly and mix well.

8, the stirred material into a template and manually tamping or mechanical vibration.

9 to 30 cm depth of each charge is appropriate.

10, at an ambient temperature above 35 ℃ or more, seven days to form removal, after form removal should prevent crashing and the local ultra-high temperature welding.

11, such as load-bearing structure of casting equipment, should be reinforced through the design.

12, after casting of concrete structures KPI acid regimen for 14 days, and after special treatment solution (factory produced) for 4 times, every 4 hours treatment time, treatment can be put into production.